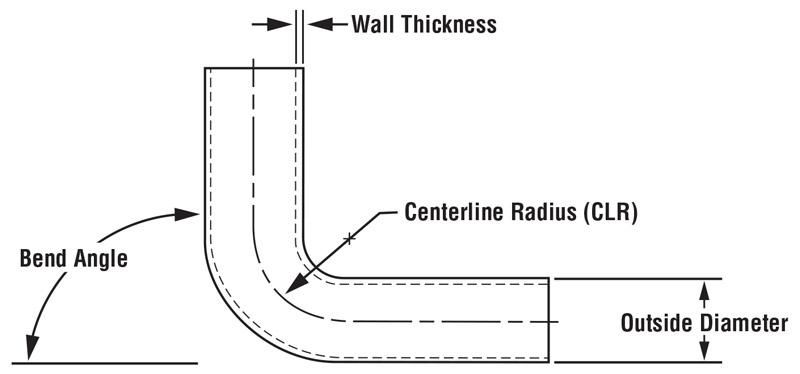

A correctly chosen procedure can help to produce consistent tolerances and precise parts.Ī material of considerable size bent with a narrow radius will have a greater chance of deforming than a smaller material bent with a larger radius. This is a key factor in deformation control. As a result, a thicker wall thickness allows a tighter bending radius and greater material extensibility with less deformation. The bending of square or rectangular tubes involves the elongation of the outer diameter (OD) of the bend and the compression of its ID. Various measures can facilitate the bending of square or rectangular tubes and reduce the amount of deformation in the bent sections: Imports Factors influencing the bending process In this picture we can see a bent tube without mandrel with a standard tool:īy submitting this form, you are consenting to receive marketing emails from: D.J.A. The standard equipment without mandrel is the simplest one, but it implies the risk of the tube deformation and wrinkles that appear internally to the tube.

There are 3 different types of equipment with which we can bend these tubes:

How can we bend square and rectangular tubes? Concavity is less problematic on thicker-walled materials. When a rectangular tube is bent, the material often has less deformation if it is bent in the hardway direction. Hardway bending requires more effort to the pipe bending machine, but with the same thickness, the deformation of the bent pipe will be less than easyway bending. In easyway bending, the greater the difference between the sides of the tube (for example, a 2-inch x 3/4-inch section has a greater difference than a 1-1/4-inch x 3/4-inch section), the greater the deformation or concavity on the inside and outside of the bending.

0 kommentar(er)

0 kommentar(er)